Teardrop Racking

Product

Contact

- Add: NO.6 Chongde Road, Cuntoucun, Hengli Town, Dong Guan City, Guang Dong Province, 523475 China

- Emial:[email protected]

- Phone: +86 13544633933

- Whatsapp: +86 13544633933

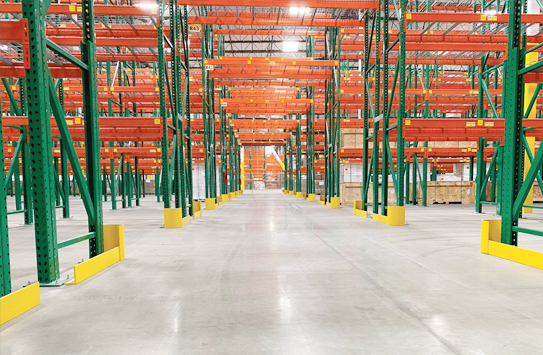

Teardrop Racking

- Phone: +86 13544633933

Advantages and features of Pallet Racking

Why Choose LIJIN Teardrop Racking System?

-

Proven Quality: LIJIN is synonymous with high-quality racking systems, designed and manufactured to international standards for exceptional durability and performance.

-

Effortless Assembly: The teardrop design simplifies assembly, enabling quick and hassle-free installation without the need for complex tools or hardware.

-

Versatility: LIJIN Teardrop Racking is highly adaptable, making it suitable for a broad range of pallet sizes and loads, ensuring that it can meet diverse storage requirements.

-

Space Optimization: This system maximizes your storage space efficiently, allowing you to make the most of available square footage and save on operational costs.

-

Safety Assurance: LIJIN Teardrop Racking is engineered to withstand heavy loads, enhancing workplace safety by reducing the risk of accidents and product damage.

-

Cost-Effective: Its space-saving and efficient design translate into long-term cost savings, making it a cost-effective choice for your storage needs.

-

Scalability: LIJIN Teardrop Racking can be expanded and adjusted as your storage requirements evolve, ensuring it remains a sustainable solution for your growing business.

-

Professional Guidance: LIJIN provides expert support, helping you select the right teardrop racking configuration to meet your specific needs.

-

Applications for LIJIN Pallet Racking

Teardrop Racking Of LIJIN finds versatile applications across various industries and settings, including:

Ideal for optimizing storage space, increasing inventory efficiency, and streamlining material handling in warehouses.

Building products and materials come in odd shapes and sizes, including sheets and long beams that require heavy-duty shelving. Cantilever racks are perfect for providing easy access to building materials without slowing down warehouse operations.

Your Professional Pallet racking suppliers

1. Warehouse Design layouts & 3D drawings

2. Rack Installation instruction

3. Quality assurancet & Best price

4. Cooperation with us can reduce a lot of time and achieve a win-win goal

Professional and fast Cantilever racking installation tutorials Racking Installation

1. Erect the uprights

2. Insert the rear beams

3. Insert the front beams

4. Measure the square

Erect the uprights: Using the chalk line as your guide, stand one upright on the outer edge and hold it in place. With the help of an assistant, erect the second across from the first. Use a level to check that the uprights are vertical. If they aren’t, place shims underneath the uprights until they are straight. Typically, a slight tilt of no more than 1/8 inch is okay, but check the installation guide for specific instructions from your manufacturer. Anchor the uprights to the floor using the recommended method in your installation guide.

Insert the rear beams: Insert the bottom rear beam first. With the help of your assistant, place the bottom rear beam in the correct slots between the two uprights, and use a mallet to secure it in place gently. If your beams do not use a slotting system, you may need to bolt them to the frame. Repeat this process with the top rear beam. Depending on the height of your uprights and racking system, you might need to use a lifting device to attach the beams and uprights.

Insert the front beams: Once you have installed and secured the two rear beams, it’s time to install the front beams. Start with the top front beam, placing it at the exact level as the top beam at the rear. Secure it like you did the rear beam, then move on to the fourth and final beam installation. Once you have installed all four beams, you have formed your first bay.

Measure the square: Before you move on to the remaining bays, use a tape measure to check that the first bay measures as a square and that all spacing is correct and equal. This is an important step, as it will save you a headache later on when installing your shelving. We will provide installation video and drawings.

Another option for assembling industrial shelving is to let a professional installer help you with your project. lijinrack is ready to respond to your needs.

There are several reasons why this may be a good option for you.

You may lack the time, supplies or available assistance to take on pallet racking assembly on your own.

Or perhaps your pallet racking design may be complex or massive and require a team of professionals to complete the racking installation to perfection.