Mobile Shelving System

Product

Contact

- Add: NO.6 Chongde Road, Cuntoucun, Hengli Town, Dong Guan City, Guang Dong Province, 523475 China

- Emial:[email protected]

- Phone: +86 13544633933

- Whatsapp: +86 13544633933

Mobile Shelving System

- Phone: +86 13544633933

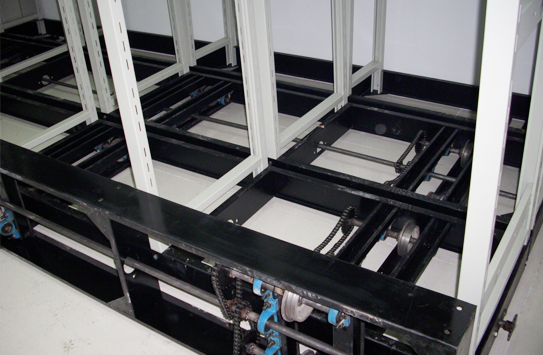

Advantages and features of Mobile Shelving System

-

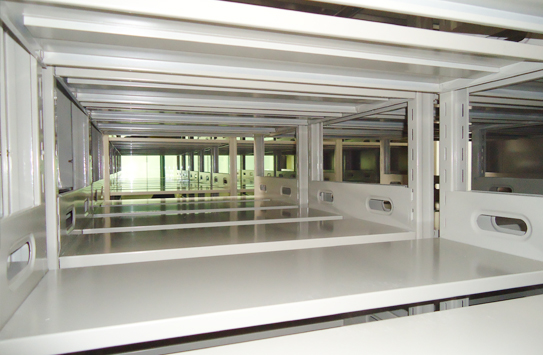

Space Efficiency: Mobile shelving systems eliminate the need for fixed aisles, maximizing storage capacity within the same floor space.

-

Enhanced Accessibility: Mobile units move along tracks, enabling easy access to specific sections, which improves organization and retrieval efficiency.

-

Customization: These systems are highly adaptable, with adjustable shelving and various unit sizes, allowing for tailored configurations to meet specific storage needs.

-

Security: Many mobile shelving systems come with locking options, providing added protection for stored items.

-

Aesthetic Appeal: Featuring modern and sleek designs, they not only enhance functionality but also improve the overall appearance of the storage area.

Why Choose LIJIN Mobile Shelving System ?

- Space Optimization: LIJIN’s Mobile Shelving System eliminates fixed aisles, significantly increasing storage capacity within the same floor space, ensuring efficient use of space resources.

- Tailored Configurations: With adjustable shelving and a variety of unit sizes, LIJIN’s system can be customized to meet your unique storage requirements, adapting to changing needs.

- Smooth Mobility: The track-mounted design ensures effortless movement, providing quick and easy access to specific sections and streamlining your organization’s operations.

- Enhanced Security: LIJIN offers optional locking mechanisms for added protection, ensuring the safety of valuable items and sensitive materials.

- Aesthetic Appeal: LIJIN’s Mobile Shelving System features a modern and attractive design, adding a touch of sophistication to your storage space and enhancing its overall appearance.

- Durability: LIJIN’s commitment to quality means their shelving systems are constructed from high-quality materials, ensuring long-lasting use.

- Ease of Installation: LIJIN’s systems are designed for easy installation, with customization options to fit the layout of your space seamlessly.

In conclusion, choosing the LIJIN Mobile Shelving System is a smart decision, as it combines space efficiency, customization, easy mobility, security, aesthetics, durability, and straightforward installation to transform your storage solutions and enhance your organization’s efficiency and aesthetics.

Applications for LIJIN Mobile Shelving System

Cantilever racking is a versatile storage solution for bulky products. Their flexibility and strength make them ideal for the industrial storage of bulky items.

Cantilever racks are used for storing the following products:

Mobile shelving systems are ideal for libraries, maximizing the storage of books and other materials while enhancing accessibility for patrons and staff.

These systems are well-suited for organizing and storing important documents and records, making retrieval efficient and secure.

Mobile shelving is perfect for storing and displaying collections, optimizing the use of space in cultural institutions.

Your Professional Cantilever racking suppliers

Online Business Directories: Websites like Alibaba, Global Sources, and Thomasnet are great resources for finding suppliers of industrial and storage solutions, including Mobile Shelving Systems.

Industry Trade Shows: Attending trade shows and exhibitions related to storage and shelving systems can connect you with reputable suppliers. Look for events in your region or consider international trade shows.

Local and National Suppliers: Depending on your location, there may be local or national suppliers specializing in storage solutions. These suppliers might offer a more personalized service and quicker deliveries.

Manufacturer Websites: Many manufacturers and suppliers have their own websites where you can find information about their products and contact details.

Business Networks: Networking within your industry or through business associations can lead to supplier recommendations and referrals.

Customer Reviews: Research and read customer reviews and testimonials to gauge the quality and reliability of potential suppliers.

Professional and fast Cantilever racking installation tutorials Racking Installation

Site Preparation: Ensure the installation site is clean, level, and free from obstructions. Verify that the floor can support the racking system’s weight.

Marking and Layout: Mark the locations for the uprights, arms, and base plates based on your layout design. Use a level and tape measure for accurate placement.

Assemble the Uprights: Begin by anchoring the uprights to the floor securely, ensuring they are plumb and level. If anchoring to concrete, use appropriate anchors.

Install the Arms: Attach the arms to the uprights, making sure they are level and evenly spaced. Tighten the bolts to secure them in place.

Install the Braces: Add horizontal and diagonal braces for stability and to prevent sway. Make sure they are securely fastened.

Secure the Bases: Anchor the base plates to the floor. This further stabilizes the structure.

Inspect and Test: Carefully inspect the entire system to ensure it’s secure and level. Test its stability by applying a load to ensure it can support the intended weight.